Flow Testing

by Ned Erkman

by Ned Erkman

Flow testing is the term used to test the air flow capability of engine components on a machine called a Flow Bench and by conducting flow tests on a flow bench the power potential of internal combustion engine components can be evaluated and determined. Modifications can also be performed to engine components and flow tested on a flow bench to improve air flow in order to develop more power and better engine performance. This means flow testing allows for further improvements in airflow research and development where standard CNC ported heads can be ported more through the process of flow bench testing to flow more air in order to develop more engine power.

Fundamentally, the internal combustion engine is an air pump that develops power based on the amount of air that flows in and out of the engine and the volume of air consumed by the engine is what determines the power production capability of the engine. Flow testing on a flow bench is an effective method used for testing the flow capability of engine components that affect engine airflow. This makes the flow bench a very important tool for evaluating the power and performance capability of engine components that flow air into and out of an engine.

The most important engine components for flowing air through an engine are the cylinder heads and the intake manifold which will ultimately determine the maximum power production capability of an internal combustion engine, since these engine airflow components create the greatest restriction to airflow by limiting the amount of air that can flow through each cylinder in the engine. This is why flow benches were originally developed to accurately test the flow capability of cylinder heads and intake manifolds in order to test, evaluate and modify cylinder heads and intake manifolds to develop more power and better performance.

Flow Testing Cylinder Heads

Intake Manifold Flow Testing

Flow Testing Sprint Car Intake

Flow benches can be used to flow test cylinder heads, intake manifolds, carburetors, throttle bodies, air intake systems, air cleaners, headers, catalytic converters and intercoolers in order to measure and evaluate the power and performance potential of these engine components based on airflow. Flow testing is very important for evaluating air flow restrictions and for predicting how much power and performance can be delivered by each engine airflow component based on CFM (Cubic Feet per Minute) airflow.

Flow Testing Catalytic Converter

Flow Testing Corvette Air Intake

Flow Testing Intercooler

Flow testing the intake port and exhaust port flow capability of cylinder heads is most important for determining the potential power that can be developed by an engine. The intake manifold flow capability is also very important since the intake manifold is an extension to the intake port of the cylinder head and it is the total flow through the intake manifold and cylinder head that determines how much power can be produced by an internal combustion engine.

This is why porting modifications that improve the airflow of cylinder heads and intake manifolds result in the best power and performance improvements to an internal combustion engiine and flow testing on a flow bench is an effective way to measure changes to airflow.

Flow Bench

The standard measure for flow testing is 28" of test pressure on a Superflow 600 flow bench.

The formula for calculating horsepower from flow test data measured at 28" of test pressure is as follows:

HP = 0.255 x flow test data at 28 inches of test pressure

Example:

Intake airflow of 250 cfm at 28" of test pressure can produce 510 hp.

250 cfm x .255 = 63.75 hp per cylinder

63.75 hp per cylinder x 8 cylinders = 510 hp.

The simple mathematical formula for calculating potential power for a V8 engine is to multiply the maximum flow bench CFM test data at 28 inches of test pressure by 2 to get the estimated horsepower capability. This means that porting modifications to cylinder heads and intake manifolds that increase airflow by 1 CFM can produce 2 horsepower in a V8 engine (1 CFM x .255 x 8 Cylinders = 2.04 HP).

Flow Testing Intake Flow

For example, a cylinder head with the intake manifold attached that flows 250 CFM through the intake port has the potential to produce 500 hp. Although this amount of intake airflow provides the potential for 2 horsepower per CFM, the engine must have the best compression ratio, the right camshaft profile and a properly tuned high flow exhaust system.

Restrictions in the air intake system must also be minimized as air flow through the entire air intake system is what determines total power output. When the intake manifold is installed on the cylinder head the intake airflow can be reduced by 2% to 30% depending on the effeciency of the intake manifold..This makes the flow effeciency of the intake manifold very important for engine performance which is why performing porting modifications to improve intake manifold airflow are conducted to develop more power by flow bench testing and tuning.

Flow Testing Exhaust Flow

It is also necessary to have the right balance of exhaust flow in relation to intake air flow in order to develop maximum power and performance. Typically a 70% intake to exhaust flow ratio is required in a naturally aspirated engine while nitrous oxide injected engines, supercharged engines and turbo charged engines require more exhaust flow to produce more efficient engine power and the lack of suffiecient exhaust flow can limit the power potential of engines equipped with these power adders.

As the term implies, an engine that is "forced inducted" which refers to supercharging and turbo charging has more intake airflow that is forced into the engine which requires more exhaust flow to discharge the larger volume of exhaust gases that are generated through forced induction.

Camshaft Development from Flow Testing

In order to achieve maximum engine power and performance it is necessary to develop cylinder heads and intake manifolds to work as a complete system and to match the flow capability of the intake manifold to the cylinder head in order to minimize flow loss. It is also important to develop the right amount of exhaust flow to discharge the intake flow that enters an engine in order to have the right balance of intake to exhaust airflow.

Once the cylinder head and intake manifold are modified and flow tested on a flow bench the flow data can be used to develop a custom camshaft profile that effectively works with the intake and exhaust flow to develop superior engine power. Developing Cylinder heads, intake manifolds and camshaft profiles through flow testing is the only way to develop superior engine performance.

Flow Testing Porting Modifications

Professional porting modifications can increase intake airflow from 20 CFM to over 80 plus CFM which can help to generate 40 to 100+ horsepower. More technologically advanced cylinder head porting modifications with larger diameter valves and high tech valvejobs can produce over 200+ horsepower. The ability to significantly improve engine airflow is what makes cylinder head porting and intake manifold porting the most important modifications for developing more power and flow testing on a flow bench is how porting modifications to cylinder heads and intake manifolds can be effectively evaluated to deliver great engine performance. Flow testing data can also be used to develop custom camshaft profiles that deliver the best engine performance.

Engine Development from Flow Testing

Flow bench tested and tuned custom cylinder head modifications, custom intake manifold porting modifications and custom designed camshaft profiles based on flow bench test data can deliver superior engine performance that sets race records and establishes engine performance standards. The ability to develop superior cylinder heads, efficient intake manifolds and custom camshaft profiles is what makes flow testing on a flow bench vital for effective engine development, which is what we do.

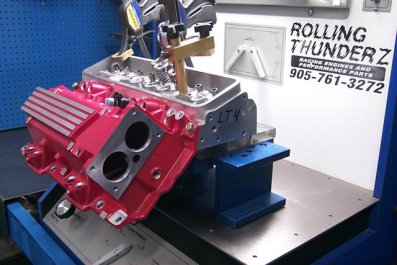

Flow Testing Corvette LT4 Intake

Viper Manifold Test

426 Hemi Manifold Flow Test